What are the precautions for enamelled wire in winding? The following enamelled wire manufacturer Y...

Enamelled wire is composed of conductor and insulating layer. The bare wire is annealed and softene...

Date:2024/03/19—21 Add:Moscow, Expocentre Fairgrounds / Mockвa, lBK «aкcпoцeнтp» The 22nd Int...

After a year of intensive preparation and construction, our new factory was successfully completed ...

For copper clad aluminum wire, copper clad aluminum wire manufacturers Xiaobian say their own views,...

2024 Vietnam (Hanoi) International Wire and Cable Exhibition From November 20th to November 22ndWe...

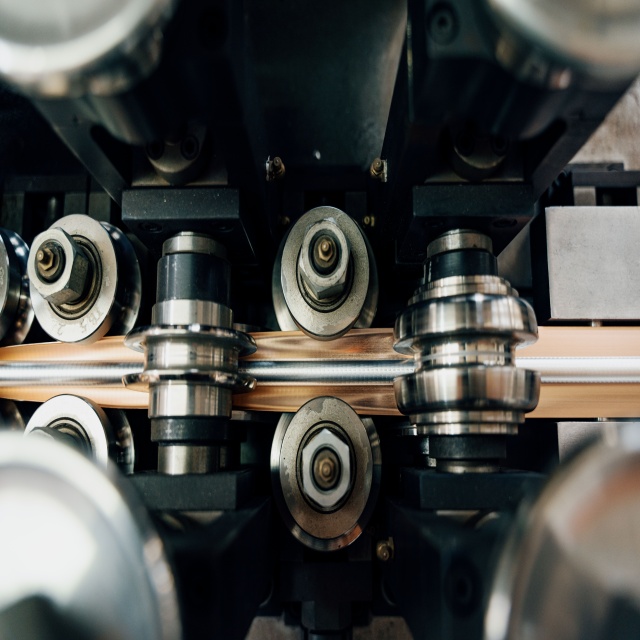

Our CCAM wire used the most advanced welding and copper plating process to produce, copper layer used 99.9% purity copper with high density and better conductivity, and ours metallurgical bonding technique assures that the copper cladding is evenly distributed around the Aluminum magnesium coil along the wire for excellent concentricity.

Our company developed the second generation of CCAM wire is made of high strength of aluminum magnesium core, copper layer is made of pure copper, light weight but boasts higher intensity of 250-300Mpa, and the density is only 2.85g/cm3, the second generation CCAM is 30% longer than its first generation CCAM competitor of the same weight. Buyer can take 30% cost reduction of using ours second generation CCAM, at the same time overcome the low-intensity antecedent that breaks easily.

|

Product name |

CCAM WIRE |

|

Diameters available [mm] Min - Max |

0.05mm-2.00mm |

|

Density [g/cm³] Nom |

2.95-4.00 |

|

Conductivity [S/m * 106] |

31-36 |

|

IACS [%] Nom |

58-65 |

|

Temperature-Coefficient [10-6/K] Min - Max |

3700 - 4200 |

|

Elongation (1)[%] Nom |

17 |

|

Tensile strength (1)[N/mm²] Nom |

170 |

|

Outer metal by volume[%] Nom |

3-22% |

|

Outer metal by weight[%] Nom |

10-52 |

|

Weldability/Solderability[--] |

++/++ |

|

Properties |

CCAM combines the advantages of Aluminum and Copper. Lower density allows weight reduction, elevated conductivity and tensile strength compared to CCA, good weldability and solderability, recommended for very fine sizes down to 0.05mm. |

|

Application |

CATV coaxial cable, large capacity communication network signal electric LAN, control signal cable, cable shielding line, metal hose etc. |

High frequency signal transmission

1. Preferred conductor material for cable TV coaxial cable;

2. 50 Ω RF cable conductor material;

3. Telephone line, electronic line, computer printing line, network line, USB and other data lines;

4. Inner conductor material of micro coaxial cable;

5. Audio and video cables;

6. Power transmission;

7. Power cable conductor material;

8. Inner conductor of control cable;

9. Inner conductor of special cables for automobiles and locomotives;

10. Building wiring conductor materials;

The copper layer uses 99.99% pure copper, which has high density and better conductivity. Our metallurgical bonding technology ensures that the copper cladding is evenly distributed around the aluminum magnesium coil along the wire, with excellent concentricity, and mechanical properties in accordance with the American ASTM B566-93 standard.

Previous : Copper Clad Steel Wire

Next : Stranded Wire

Anhui Yuxin Metal Products Co. , Ltd. located in Xuancheng economic and technological development zone....Read More >

No.228 Qiushi Road, Economic & Technology Development Zone, Xuancheng City, Anhui Province, China.

rick@cnccawire.com

0563-2022783

086 19159330197

086 19159330197

Copyright © 2024 Anhui Yuxin Metal Products Co. , Ltd.